In regions like the UAE and Saudi Arabia, where sunlight is abundant but temperatures can exceed 50°C, technicians require tools that can endure extreme heat while maintaining precision.

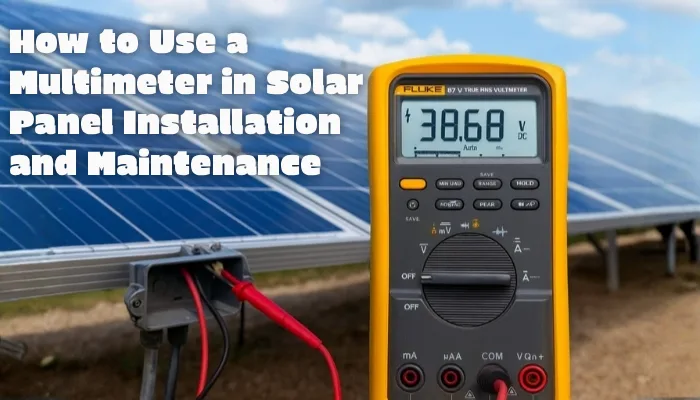

A solar multimeter is one of the most essential instruments in every solar engineer’s toolkit — enabling safe installation, testing, and maintenance of photovoltaic (PV) systems.This guide explains how to use a multimeter in solar panel installation, what measurements matter most, and how leading brands like Fluke and Hioki design specialized models optimized for solar work.

Why Solar Technicians Need a Dedicated Multimeter

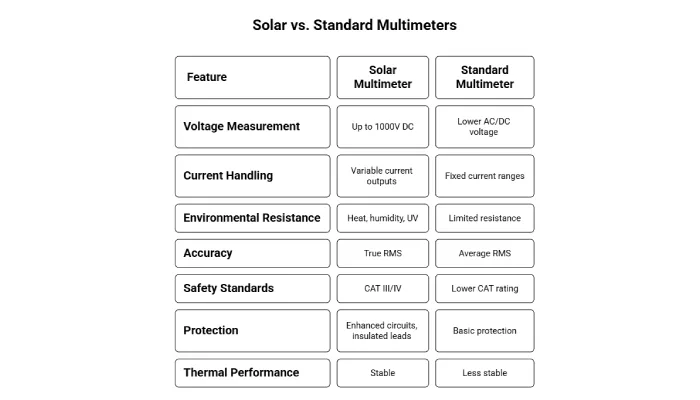

Solar power systems operate differently from traditional AC circuits.

PV modules generate direct current (DC) that can vary based on sunlight intensity, temperature, and load.

Therefore, a solar engineer needs a multimeter that can:

- Measure high DC voltages (up to 1000V)

- Handle variable current outputs safely

- Resist heat, humidity, and UV exposure

- Provide True RMS accuracy for mixed signal environments

- Comply with CAT III or CAT IV safety standards

Standard household multimeters are not built for such demands.

Solar-specific models are designed with enhanced protection circuits, insulated test leads, and stable thermal performance, making them ideal for rooftop and fieldwork in hot climates.

Understanding Solar System Measurements

Before diving into how to test solar panels, it’s important to understand the key measurements required for diagnosing PV performance.

A multimeter can perform the following functions during installation and maintenance:

1. DC Voltage Measurement

This is the primary function in solar diagnostics.

Each panel’s voltage helps determine the system’s open-circuit voltage (Voc) and operating voltage under load (Vmp).

Using a True RMS multimeter like the Fluke 87V ensures stable readings even when sunlight fluctuates.

2. Current Measurement

Measuring current output is crucial for identifying shading or wiring issues.

Using a multimeter with a clamp accessory allows safe DC current measurement without disconnecting wires.

For example, Hioki’s DC clamp meters integrate seamlessly with their digital multimeters for solar work.

3. Resistance and Continuity Testing

Resistance tests help locate cable faults or poor connections, while continuity checks confirm that fuses and diodes within the junction boxes are functioning properly.

This ensures safe current flow across the PV array.

4. Temperature Measurement

Panel temperature significantly affects voltage output.

A built-in or external K-type thermocouple lets technicians monitor surface temperature, correlating it with voltage losses during performance analysis.

How to Test a Solar Panel with a Multimeter

Here’s a step-by-step guide for using your multimeter to test solar panels safely and accurately:

- Safety First: Wear insulated gloves and use CAT IV-rated test leads. Ensure panels are disconnected from inverters.

- Check Open-Circuit Voltage (Voc):

Set your multimeter to DC voltage, connect the positive probe to the panel’s positive terminal and the negative probe to the negative terminal.

Compare the reading with the manufacturer’s specified Voc on the nameplate.

A lower reading may indicate degradation or partial shading. - Measure Short-Circuit Current (Isc):

Switch the multimeter to the current (A) mode, set the range appropriately, and connect across the terminals briefly.

Compare the measured Isc with the panel datasheet value. - Inspect Diode Health:

Use the diode test function to ensure bypass diodes are intact, preventing hot spots on solar cells. - Temperature Correlation:

Measure panel temperature and record it alongside voltage readings.

A rise in temperature typically lowers voltage by about 0.4–0.5% per °C.

By following these steps, technicians can quickly determine whether a solar panel is operating efficiently or requires replacement.

Fluke Multimeters for Solar Professionals

Fluke has established itself as a global leader in test and measurement technology, particularly in renewable energy sectors.

Their multimeters are built for extreme durability, precision, and field safety.

Models like the Fluke 393 FC Solar Clamp Meter and Fluke 87V Industrial Multimeter are among the most trusted for solar maintenance in the GCC.

Popular Fluke Models for Solar Work

| Model | Max Voltage (DC) | Features | Safety Rating | Ideal Use |

|---|---|---|---|---|

| Fluke 393 FC | 1500V DC | True RMS, solar clamp, wireless logging | CAT III 1500V / CAT IV 600V | PV installation and commissioning |

| Fluke 87V | 1000V DC | High accuracy, temperature measurement | CAT IV 600V | Panel diagnostics and inverter testing |

|

Fluke 283FC |

600V DC | Compact, reliable, entry-level | CAT III 1500 V / CAT IV 1000 V | Industrial electrical panels, data centers, for Solar Applications |

Hioki, a Japanese precision brand, offers multimeters designed for high-accuracy voltage testing and thermal stability.

Their instruments excel in laboratory-grade measurements while maintaining the durability required for field environments.

In hot climates such as Riyadh or Abu Dhabi, Hioki devices maintain calibration stability longer than many competitors.

Recommended Hioki Models for Solar Technicians

- Hioki DT4282: Advanced True RMS multimeter with ±0.03% accuracy and high-speed response, ideal for solar inverter analysis.

- Hioki DT4256: Compact True RMS meter suitable for both field and lab use with excellent display clarity.

- Hioki CM4375: AC/DC clamp meter that integrates safely with PV wiring systems for current diagnostics.

Both Fluke and Hioki offer data logging options, allowing solar teams to track system performance trends over time — essential for predictive maintenance.

Common Solar Multimeter Mistakes to Avoid

Even experienced technicians can make errors when testing PV systems.

Here are frequent mistakes and how to avoid them:

- Measuring current directly without clamp mode: This can damage the meter or cause short circuits.

- Ignoring temperature correction: Voltage readings vary with heat; always measure panel surface temperature.

- Using non-CAT-rated tools: In high-voltage systems, this is a severe safety risk.

- Failing to check polarity: Reversed connections can damage the meter or the panel diodes.

- Skipping calibration: Always verify calibration every 6–12 months for accurate results.

Maintenance Tips for Solar Multimeters in Hot Climates

Because technicians in the Gulf region often work outdoors under extreme sunlight, maintaining the multimeter properly ensures longevity and reliability.

Follow these maintenance steps:

- Store the multimeter in a shaded, dry area when not in use.

- Avoid prolonged exposure to direct sunlight — heat buildup can affect internal circuits.

- Clean the display and terminals regularly using a soft cloth.

- Check the insulation of test leads periodically.

- Perform functionality tests monthly, especially after working in dusty environments.

Proper care ensures your multimeter delivers accurate readings even after years of intensive solar fieldwork.

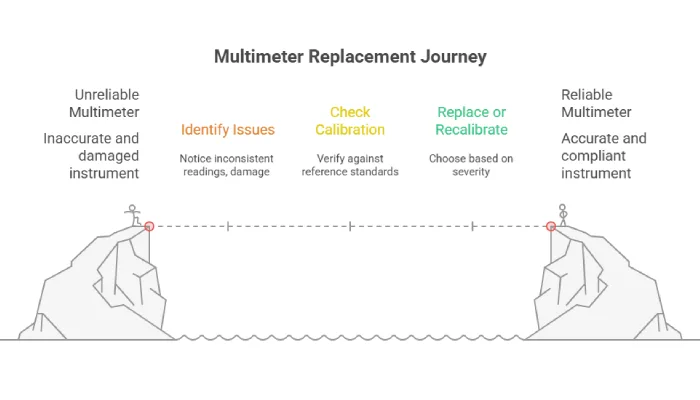

When to Replace Your Multimeter

No instrument lasts forever.

Replace or recalibrate your solar multimeter when you notice:

- Inconsistent voltage readings compared to reference panels

- Physical damage or cracks in casing

- Display flickering or delay

- Battery leakage or corrosion

- Frequent fuse blowouts

For professional environments, it’s best to maintain a calibration log and ensure your multimeter complies with ISO or IEC testing standards.

Where to Buy Solar Multimeters in UAE & Saudi Arabia

Authorized distributors ensure you get original, calibrated instruments with warranty and after-sales service.

In the Gulf, MME Electronics offers a comprehensive selection of high-quality multimeters from leading manufacturers in the field, specifically optimized for solar testing.

By purchasing from a trusted vendor, you gain access to technical support, calibration certificates, and genuine accessories — all critical for maintaining compliance and performance in large-scale solar operations.

Conclusion

Solar energy systems demand reliable and precise measurement tools — and multimeters are the backbone of every successful installation.

Whether you’re verifying open-circuit voltage, diagnosing faulty connections, or maintaining entire solar farms in the UAE or KSA, using the right multimeter ensures both safety and efficiency.

Leading manufacturers in the industry continue to set the benchmark for solar testing accuracy, durability, and professional-grade performance.

Investing in a certified multimeter from MME Electronics means you’re not only buying a tool — you’re buying reliability under the harshest Gulf conditions.

Bench Multimeters

Bench Multimeters