FLIR TG165-X Thermal Camera

Hioki IR4056-20 Insulation Tester

$0.00 (excl.VAT)Megger Mit525 UK Insulation Resistance Tester

$0.00 (excl.VAT)FLIR TG165-X Thermal Camera

What is a multifunction tester?

A multifunction tester is a versatile instrument used primarily in the electrical industry to assess various aspects of electrical installations. This device simplifies complex tests and combines the functionalities of several separate testing instruments into one portable unit.

These testers are invaluable in ensuring that electrical systems meet regulatory standards and are safe for use. They are widely used by electricians and technicians during installation, troubleshooting, and routine maintenance of electrical systems, offering a comprehensive solution that enhances efficiency and accuracy in the field.

These devices are engineered to conduct various electrical tests, including:

- ✅ Voltage and current measurement – Essential for checking electrical supply consistency.

- ✅ Resistance and continuity testing – Ensures secure and efficient circuit connections.

- ✅ Insulation resistance testing – Validates the integrity of electrical insulation.

- ✅Loop impedance and short-circuit current measurement – Ensures the effectiveness of protective circuits.

- ✅ RCD (Residual Current Device) testing – Enhances electrical safety by verifying protective devices.

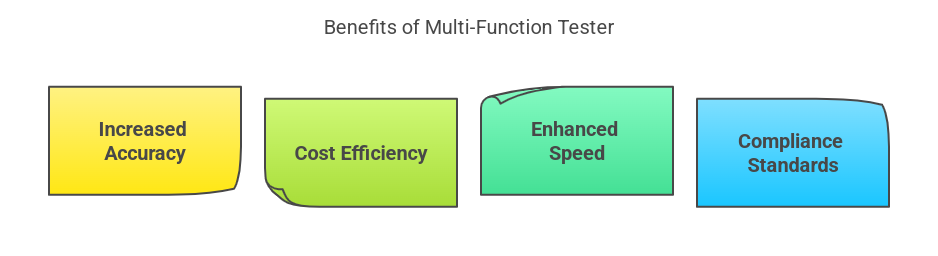

Why is a Multi-Function Tester Essential?

In today’s advanced electrical systems, professionals must adhere to strict safety regulations and industry standards. A high-quality multi-function tester plays a critical role in ensuring compliance and improving workflow efficiency.

- ✔ Increased Accuracy and Reduced Errors – Advanced sensors and precision engineering provide reliable results.

- ✔ Cost and Space Efficiency – Replaces multiple testing tools, reducing investment costs and toolbag weight.

- ✔ Enhanced Testing Speed and Troubleshooting – Enables rapid diagnostics, boosting productivity.

- ✔ Compliance with Electrical Safety Standards – Meets international regulations like IEC, IEEE, and BS EN standards.

Applications of a multifunction tester

Multifunction testers are widely used across various industries due to their diverse capabilities. Some key applications include:

- Continuity testing and resistance measurement: Verifying electrical connections and identifying faults in circuits.

- Insulation resistance testing: Ensuring the integrity of electrical insulation in cables and equipment.

- Loop impedance measurement: Evaluating the effectiveness of protective circuits and ensuring adequate current flow for protective devices.

- Short-circuit current measurement: Assessing the response of protective systems in case of a fault.

- RCD testing: Checking the functionality of residual current devices for enhanced electrical safety.

- Voltage measurement: Measuring voltage levels across different electrical systems, from low-voltage to high-voltage industrial setups.

- Phase sequence and rotation testing: Ensuring correct motor rotation and phase sequence in three-phase systems.

- Earth resistance measurement: Assessing ground connection quality and ensuring the proper operation of protective grounding systems.

Types of multifunction Testers

Multifunction testers come in various models, each designed for different needs. Some of the main types include:

1. Basic Multi-Function Testers

These models are designed for standard electrical testing needs and typically include continuity, insulation resistance, and loop impedance testing. They are ideal for routine maintenance and basic troubleshooting.

✔ Designed for standard electrical testing (continuity, insulation, loop impedance).

✔ Best for electricians handling routine installations and maintenance.

2. Advanced Multi-Function Testers

These devices offer additional features such as RCD testing, earth resistance measurement, and phase sequence detection, making them suitable for complex installations.

✔ Includes RCD testing, earth resistance measurement, and phase sequence analysis.

✔ Ideal for industrial-grade and complex electrical systems.

3. Multi-Function Calibrators

Used for calibration and precision verification of other testing equipment, these devices can generate and measure voltage, current, and frequency.

✔ Used for calibration of measurement instruments, ensuring accuracy.

✔ Essential for quality control labs and precision engineering industries.

4. Digital Multi-Function Testers

Featuring digital displays, data logging, and wireless connectivity, these testers provide enhanced usability and accuracy.

✔ Features LCD screens, data logging, and wireless connectivity.

✔ Enhances usability with real-time data analysis and reporting capabilities.

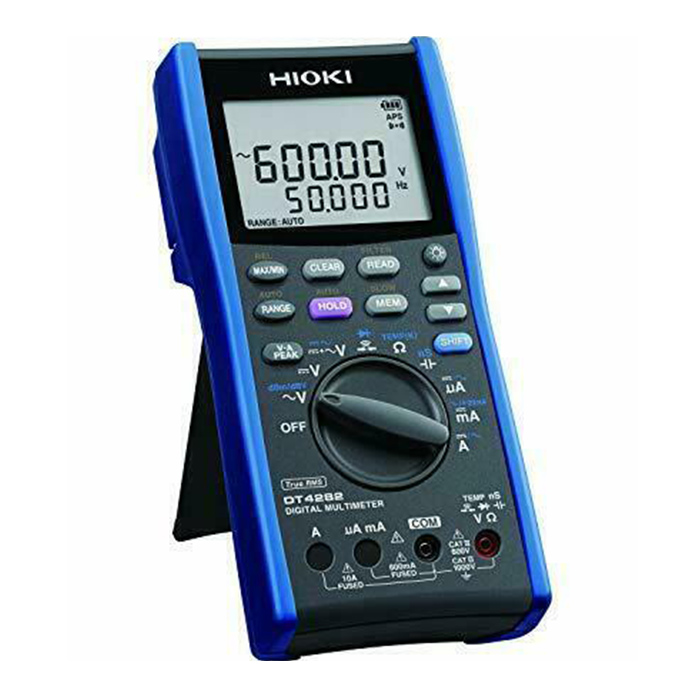

5. Handheld Multi-Function Testers

Compact and portable, these testers are ideal for fieldwork, featuring ergonomic designs and rugged construction for harsh environments.

✔ Compact, portable, and rugged, designed for field engineers.

✔ Built for harsh environments like construction sites and outdoor installations.

Types of multifunction Testers

How to Use a Multifunction Tester

To ensure optimal usage of a multifunction tester, follow these steps:

- Continuity testing: Connect the probes to the circuit and listen for an audible beep or observe a near-zero reading.

- Insulation resistance testing: Set the device to insulation mode, connect the probes, and record the displayed resistance value.

- Loop impedance testing: Connect the tester to the circuit, measure impedance, and analyze the results.

- RCD testing: Connect to protective circuits and evaluate the performance of residual current devices.

- Earth resistance testing: Measure the resistance of the grounding system to ensure proper safety levels.

Buying Guide for a Multifunction Tester

Selecting the right device requires considering several factors:

- Work requirements: Determine the specific tests that will be performed most frequently.

- Accuracy and precision: Choose testers with high measurement accuracy and calibration capabilities.

- Ease of use: Look for devices with clear displays and user-friendly interfaces.

- Additional features: Consider options such as data logging, wireless connectivity, and color screens.

- Durability and resistance: Opt for robust models designed for industrial environments.

- Price and warranty: Ensure that the chosen device offers good value for money and comes with a reliable warranty.

Multi-function testers are essential tools in the electrical and electronics industry, enabling professionals to perform a wide range of tests with a single device. Choosing the right tester depends on work requirements, accuracy needs, additional features, and budget constraints. By investing in a suitable multi-function tester, professionals can enhance efficiency, improve safety, and ensure compliance with electrical standards. These testers provide a smart and effective solution for accurate electrical testing and troubleshooting, making them indispensable for engineers and technicians alike.

About the Author :

I’m Mahboubeh Jahebi, a content writer and SEO expert with over 5 years of experience in industrial equipment and precision measurement technologies. I’ve worked with international brands and contributed to the content strategy of Mohammad Mahdi Electronics (MME), a leading supplier of test instruments in the Middle East.

Bench Multimeters

Bench Multimeters